Precision Design

Precision Design

An automobile, be it a sports car, van, truck, RV, or vehicle designed for construction, is going to have a ubiquity of mechanical components that are often incredibly minute. Today it’s commonplace for there to be computers in many vehicles, and these have electrical components that are incredibly precise, requiring top-tier manufacturing.

In the same vein, when it comes to medical equipment, there are going to be a lot of precise components involved which need very professional development and reliable manufacture. Whether used by a plastic surgeonor a heart surgeon, sometimes the metallic components are of the most minute variety, think “wristwatch”, and even smaller.

Similarities Between The Sawbones And The Grease Monkey

With this in mind, it’s interesting to consider that the classic analogy between a human body and a vehicle has even more validity. When your vehicle has a problem, you’ve got to take it into a mechanic. The mechanic reviews the vehicle’s operations, does a few things which help narrow the problem down, and either fixes it or replaces a bad component.

A medical doctor essentially does exactly the same thing. He or she looks at a patient, narrows down what may or may not be the problem, and then fixes what is discovered to be the “bad” culprit in the “mechanical” system of the body.

Now when your vehicle is sick, do you want a car doctor using rickety, self-sourced components that have been cobbled together out of necessity over time? When your body is sick, do you want a humanity mechanic cutting you open and jerry-rigging an internal fix with some solution involving non-biodegradable plastics and chutzpah?

No! In both scenarios, you want mechanics and surgeons using vetted equipment from top-tier designers. And, to that end, it makes sense that solutions be searched out which utilize the latest in precision manufacture. Metal work today inhabits practically every echelon of life. From spectacles to keychains, medical examination equipment to car maintenance tools, and everywhere in between.

Sourcing A Parts Provider Known For Precision Design

When you’re searching for an automotive medical stamping company, you want one like Weiss-Aug.com, who have been around for decades—according to the site: “Over 40 years ago, Weiss-Aug started as a stamping company, focusing on complex, high-precision and miniature high-speed stamping.”

A company that’s been around for such a period of time is able to identify which production solutions are cost-effective and dependable. This means for auto manufacturers requiring parts for assembly, a great deal of expense can be curtailed through bulk purchases. The same is true for mechanics and surgeons requiring intricately designed equipment.

When you can buy tools that have been made with the finest components, those tools are more dependable, and begin to represent a kind of investment. A hammer can be an investment if it outlasts competitive options that perform the same task. A sixty-dollar hammer that lasts twenty years is better than twenty four-dollar hammers that each last a year.

Remaining Technologically Relevant

Sometimes you don’t need to buy in bulk, sometimes you just need a single part that has worn out or been compromised. Likewise, when you need such solutions, going through a metal stamping agency known for precision and effectiveness over various decades makes a lot of sense.

Technology marches on, and maximizing your investment in various solutions, from cars to medical equipment, is essential to expense reduction. It’s integral to source solutions of a professional, vetted quality. When these have a slightly higher price tag, it’s a good thing—remember the hammer. Those solutions which are designed with greater quality last longer.

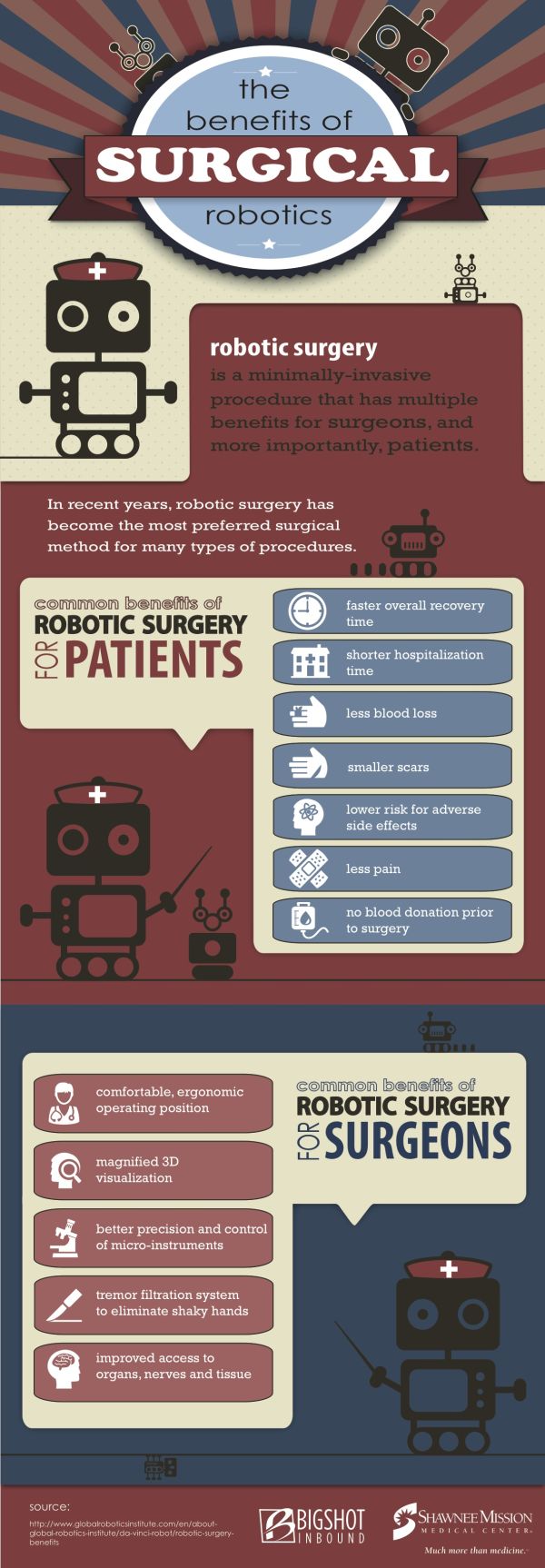

How Robotics Technology Can Benefit Surgeons