Before getting started with how the dewatering technology satiates oil containment requirements, let’s quickly touch base with a run-through on the dewatering process and what it entails.

In Layman’s terminology, dewatering is the process of extracting water from the soil or a solid material through centrifugation, wet classification, filtration, or related solid-liquid separation methods. These methods include the elimination of residual liquid from a filter cake employing a filter press as a component of diverse industrial processes. Dewatering pumps required for this process are the centrifugal pumps that are installed in buildings situated below the groundwater level- such as vaults, maintenance hole, underground mining- to dwindle the water level and then sustain it at a certain height.

Dewatering Pump Technology takes care of your oil containment needs.

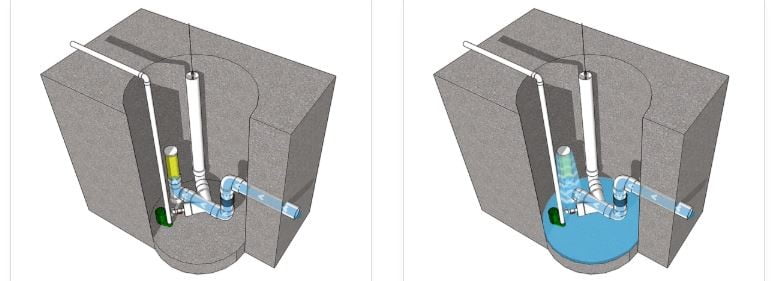

Dewatering technology has consistently and significantly evolved over the years. Having exclusive traits and benefits along with versatile applications across several industries, it has even revolutionized sectors requiring oil containment. There are customized dewatering pumps that have been specifically designed to render a low-maintenance, cost-efficient solution for oil containment. They are a pocket-friendly alternative to exorbitant oil-water separators and manual dewatering systems used in underground vaults and maintenance holes. An automatic and adaptable dewatering system filters and evacuates water from secondary containment sumps and vaults. During any event involving significant oil release, the adaptive alternative technology used here ensures that the dewatering systems’ central filter core solidifies and creates a barrier to avoid any passage of the stored liquid.

This cutting-edge dewatering pump system uses oil containment technology for a safe, acquiescent water discharge solution in applications where a sump pump or an automatic pump is used. It helps to resolve problems such as the risk of hydrocarbons, chronic water intrusion, and sediment issues. Such situations arise in areas having oil or fuel appliances, accumulating oil and water- such as elevator shafts, utility vaults, and so on. The filtering technology integrated into these dewatering pump systems eliminates the possibility of an oil discharge, thus rendering absolute oil containment.

Tip: As a buyer or manufacturer, ensure these dewatering pumps are customized for site-specific oil containment applications and also fulfills Federal SPCC mandates

Given below is an elucidation on the various ways this dewatering technology is a boon that will help adhere to your oil containment requirements.

- The advanced technology involved here saves crew time from a recurring, mechanical dewatering process

- Diverse models are designed and made available to cater to any site-specific application

- The dewatering pump enables secure, untended wastewater exudations

- It provides full containment ensuring that no sediment or hydrocarbons pass through

- It ascertains compliance and facilitation of water discharge needs

- Furthermore, it ensures that the oil & fuel-specific equipment used in vaults are in working order

VIPOR-SOWF (Sump Oil Water Filtration) Dewatering Pump

Several types of unique dewatering pump systems are available in the market to meet the oil containment needs and requirements. The trademark VIPOR dewatering pumping systems are an ideal example of the revolutionary dewatering technology. They are used for sump oil-water filtration, and during oil discharge, they can polish and capture sheen while expelling water using total shutoff capabilities. VIPOR pumping systems also remove hydrocarbons and other volatile organic compounds from the water to a non-detectable level while catering to the SPCC regulations. If there is an occurrence of massive hydrocarbon release, the advanced technology used in such pumping systems ensures that the flow stops right away.

Note: Even though some of these specially designed oil containment dewatering pumps are similar to the oil-detecting pumps available in the market, the avant-garde technology used in the former prevents sheen from passing through

Did you know? The leading-edge technology used in making these pumping models for oil containments release the filtered water through gravity flow, and into the circumambient ground area

Some of these modern dewatering pumps have the broad application owing to their versatility. They can function well without a sump or a crock, requiring just a free discharge area. Such dewatering pumps are generally used to retrofit existing concrete moat containment. Some of them, such as the trademark VIPOR-SUMP dewatering system, are specifically tailored to be used in transformer vaults having an existing sump crock. Unlike the oil-water separator, these dewatering pumps have an add-on benefit of averting any sheen from passing through.

Furthermore, unlike unreliable oil switches, the filtering technology used here eliminates the possibility of an oil discharge, thus ensuring full oil containment. Whether it is retrofitting existing containment or concrete moats with no drainage capabilities, to find the ideal dewatering pump, it is crucial to identify the primary source of concern as well as be aware of the expectations of a customer.

Tip: Depending on site-specific variables, every situation and consequent requirement(s) of dewatering pumps will be different. So, it’s a smart practice to figure out the ideal manufacturer for your needs and directly contact them to discuss your unique oil containment requirements