Brazed heat exchangers are a vital part of many industrial processes, providing efficient and reliable heat transfer to ensure the optimal performance of equipment. By understanding the benefits of brazed heat exchangers, you can ensure the process runs smoothly and efficiently with minimal downtime or costly repairs.

Advantages of Using a Brazed Heat Exchanger

A brazed heat exchanger has several advantages over other types of heat exchangers. One of the biggest advantages is its efficiency. Because the brazing process creates a strong, leak-proof joint between the plates, there is very little heat loss, and the exchanger can operate efficiently.

Compact size is another benefit of a brazed heat exchanger. The exchanger’s overall size is significantly less than that of other kinds of exchangers since the plates are so thin and closely spaced. This makes it perfect for applications requiring premium space or use in compact places.

Durability is another advantage of a brazed heat exchanger. The exchanger will survive for many years with no maintenance because the plates are brazed together and there are no joints or welds that could break or fail over time.

A brazed heat exchanger offers these advantages in addition to being highly corrosion-resistant and able to withstand a range of temperatures and fluids. Due to its design, it is perfect for a variety of processes in the industrial, HVAC, and refrigeration industries.

How Does a Brazed Heat Exchanger Works?

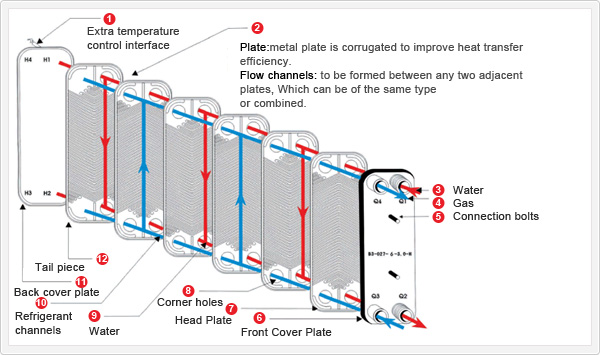

A brazed heat exchanger is a device that helps move heat from one place to another. It has metal plates with tiny gaps between them, and the liquid moves through the gaps, transferring the heat. The metal plates are held together by a brazing material which helps keep the liquid in place and ensures it can do its job properly.

The brazing material used in the heat exchanger is usually a high-temperature resistant alloy with a melting point higher than the operating temperature. This means the brazed connections remain intact during operation, ensuring efficient heat transfer and reducing leakages. It also helps ensure no contamination from other materials occurs within the system.

The liquid moving through the gaps in the brazed heat exchanger can be water, glycol, or other liquids, depending on its use. The heat exchange rate depends on factors such as the size of the gap between plates, the type and amount of liquid used, and even its temperature.

A brazed heat exchanger is a great solution for many different applications. It is highly efficient at moving heat and helps keep the system running safely and reliably. Its low-maintenance design makes it ideal for those looking to avoid costly repairs. Plus, its compact size allows for easy installation in tight spaces. These benefits make a brazed heat exchanger an excellent choice for many applications.

Different Types of Brazed Heat Exchangers are Available

Brazed heat exchangers use metal to transfer heat from one place to another. They come in different shapes and sizes, like tubes, plates, and blocks. Tube heat exchangers are the most common type, and they’re used when transferring heat between two fluids of different temperatures.

Plate heat exchangers have multiple plates that can transfer heat from a hot fluid to a cold one, while block-style exchangers use a series of blocks arranged in a pattern that helps to increase heat transfer efficiency.

No matter the type of exchanger you choose, brazed heat exchangers are designed to provide superior thermal performance with little maintenance required. This is due to their strong metal construction that eliminates potential sites for corrosion or leakages.

Additionally, brazed heat exchangers can be used in various applications, from industrial processes to residential systems. And because of their compact size, they can be used in spaces with limited room, making them ideal for many applications where space is a major concern.

Considerations When Choosing a Brazed Exchanger

A brazed heat exchanger is a type of heat exchanger that is made up of multiple thin, corrugated metal plates that are brazed together. It is an efficient and cost-effective solution for heating or cooling fluids in various applications, including HVAC, refrigeration, and industrial processes.

When choosing a brazed heat exchanger for your needs, there are several key considerations to remember.

First and foremost is the material of the plates. Common materials include stainless steel, copper, and nickel alloys, each with benefits and drawbacks. Stainless steel is durable and corrosion-resistant, copper has excellent thermal conductivity, and nickel alloys are often used in high-temperature applications.

Another important factor to consider is the design of the plate heat exchanger. Different designs can impact the unit’s efficiency, pressure drop, and flow rate. Some common designs include parallel flow, counterflow, and crossflow configurations.

Size is also an important consideration when selecting a brazed heat exchanger. The size of the unit will depend on factors such as the volume of fluid to be heated or cooled, the required temperature range and the pressure drop across the unit.

In addition, it is important to think about the operating conditions of the heat exchanger. Factors such as temperature, pressure, and fluid characteristics can all impact the performance and longevity of the unit. To meet the application’s needs, it may be necessary to select a brazed heat exchanger with specific features, such as a high-pressure rating or chemical resistance.

Finally, when selecting a brazed heat exchanger, it is important to consider the overall cost of ownership. While initial costs may be lower for some models, ongoing maintenance and repair costs can increase. A high-quality, durable unit may cost more upfront but can ultimately provide a better return on investment.

Conclusion

Choosing the right brazed heat exchanger for your application can be daunting. But understanding how they work and what types of exchangers are available can help you make an informed decision that will benefit your business in the long run.

Brazed heat exchangers offer many advantages over other systems, including increased efficiency and cost savings due to minimal maintenance requirements. Consider all factors before purchasing to choose the best option for your specific needs. With careful selection and proper installation, a brazed heat exchanger system should provide reliable performance while helping reduce energy costs and improve operational efficiency.