A pump is a critical component of any hydraulic system. They provide a way to transfer the hydraulic fluid from the reservoir to the rest of the system. Delivering the fluid at pressure is another job of a pump. This can be accomplished with a multitude of different pump designs and configurations. Each of these will have advantages and disadvantages and often depend on the application they are to be used in.

Types of Hydraulic Pumps

Sourcing a hydraulic pump is not always the most straightforward exercise. There are a number of different types and even sub-types that exist. Here are just a few examples of the available choices:

- Rotary pump

- Gear pump

- Screw pump

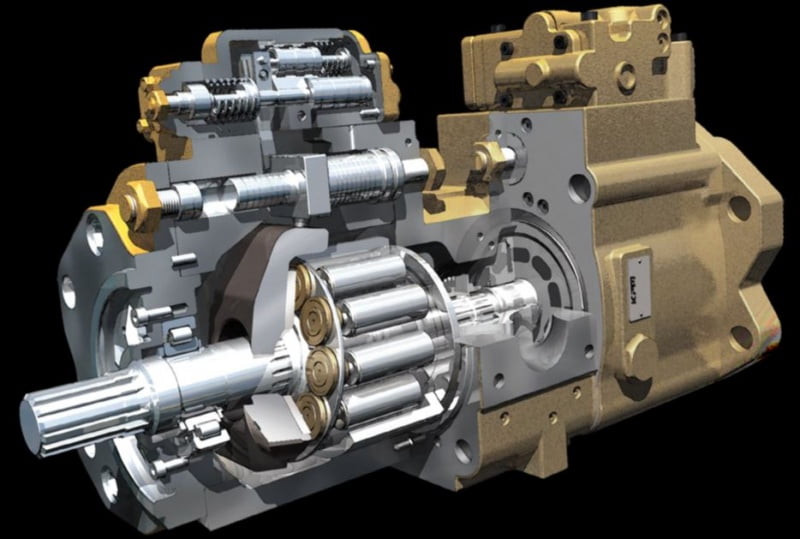

- Piston pump

- Lobe pump

Fortunately, the names are descriptive enough to understand the basic operation. Gear pumps are driven by a series of mechanical gears. Screw pumps utilize meshed screws in a chamber. Within each category, there are often more detailed classifications. Some examples are external or internal gear pumps, and axial or inline hydraulic piston pumps.

Design Factors

Selecting the right one can depend on a number of factors. If chosen incorrectly, the pump could be placed in a situation where it will prematurely fail. At a lesser extreme the pump may be inefficient or become unreliable. Below are just a few things to consider when deciding on what is best for your application.

- Pressure – Understanding the pressures involved is key. A pump that provides too little pressure may not be acceptable, while too high of pressure may cause failure.

- Flow rate – Knowing how much fluid needs to be delivered at the output is also important.

- Size – The size and weight of pump types can vary and may be a reason to consider one over the other.

- Environment – Pumps that need to function in harsh environments will need special consideration. Examples include extreme temperatures or exposure to harmful chemicals.

You won’t want a pump to be working too hard to achieve the desired pressure and flow rate. This is where inefficiency comes in. You may have a system that does not operate with consistent inputs and will need greater flexibility. Certain pump designs are more suited to adapting to such changes.

Choosing the best hydraulic pump for your application is critical. There are several aspects that go into making this decision. Speaking with a manufacturer or distributor with extensive knowledge can help remove some of the guesswork.