The industrial revolution capitalised on the standardisation of products which resulted in an increased efficiency in manufacturing. However, with the evolution of technology and the conceptualisation of innovative ideas, things have taken a different turn.

The industrial revolution capitalised on the standardisation of products which resulted in an increased efficiency in manufacturing. However, with the evolution of technology and the conceptualisation of innovative ideas, things have taken a different turn.

With the vastly different customer preferences and their rising expectations, the concept of customisation has gained traction. Every individual’s requirement and expectation out of a certain product are different from the other. Therefore, mass production falls short of meeting their needs.

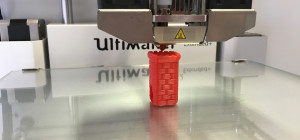

The value of craftsmanship and enhanced personalisation has increased among consumers. 3D printing blends these two aspects seamlessly. Over the years, 3D printing has become an effective tool for rapid prototyping. 3D printing is quickly being implemented in various industries owing to the numerous benefits that it provides.

Let’s take a look at some of the environmental impacts of 3D printing.

Reduced Requirement for Transportation of Products

The logistics behind a product is extremely complex in case of conventional methods and involves transporting the products over long distances, sometimes across continents. From transportation of raw materials to the shipment of the finished products, the entire process can affect the environment. 3D printing does away with this problem by manufacturing the products locally.

With 3D printing, you can choose an item from a catalogue and get it printed as close to home as possible. However, raw materials would still be required to be transported to the location of production. This makes the process cost-effective and less time-consuming.

Another positive effect of reduced shipping would be the reduction in the usage of fossil fuel. This will reduce pollution considerably.

According to Peter Weijmarshausen, co-founder of Shapeways, a 3D printing company, “[i]magine a world in which you can get exactly what you want, and not what is just available…Imagine if you only made what you need, or imagine if you are a designer and could bring your product to market in days, not years. Imagine products that can all be made locally. 3-D printing is relevant for everyone, regardless of your technological background.”

Increased Recycling

Recycling has a major positive impact on the environment. 3D printing makes this possible. Recycled materials can be used as raw materials for the 3D printers to print with. Apart from raw materials, parts of a 3D printer can be produced by recycled materials. For example, plastics, metals and other materials can be ground and used to make filaments for 3D printers.

3D printing houses has turned out to be an exciting trend recently. Recycled materials are being used for printing out 3D property to increase the quality and cost-effectiveness of the process. For example, a Brazilian start-up has been thinking about creating a type of concrete with the help of recycled composites. The houses printed with this material will be 30% cheaper on average. With the evolution of this technology, this process is expected to become 80% cheaper. The process would also become ten times faster than other construction processes.

In addition to that, the 3D printed products are created with single raw materials. Recycling these materials is a simple process. This increases the efficiency of the 3D printing process.

Reduced Wastage of Materials

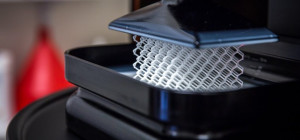

Also known as additive manufacturing, the process of 3D printing involves the deposition of one layer of raw material over another to create the final product.

Unlike 3D printing, other methods of manufacturing are subtractive. This means that a finished product does not use the entire raw material. For example, while building a chair, the entire lumber is not used. A lot of wastage of raw materials is produced. This method is applicable for anything produced with the help of tradition manufacturing methods includes wastage of raw materials.

This wastage may end up in the landfill, thus harming the environment considerably. Unlike the conventional methods, 3D printing cuts back on the wastage.

Increased Lifetime of Products

With the commercialisation of 3D printers, the need to buy replacement parts for various equipment has reduced. 3D printing has made it possible to print out replacement parts right from the comfort of our homes. In addition to that, we no longer need to throw away old equipment since improved and efficient parts can be printed out in no time. Therefore, this process is not only cost-effective but also reduces waste significantly.