CNC machines are used for cutting a range of metal and non-metal materials. The cutting tools are managed by computer numerical controls and they employ various technologies to cut steel, wood, plastic and other materials. Two of the popular technologies employed by CNC machines for slicing different items are water-jet and plasma.

Both plasma and water-jet CNC machines can be used for slicing numerous metal and non-metal materials. If you are planning to invest in a CNC machine, your obvious question must be, which one is better for your business; however, the answer is not so straightforward. Whether you choose water-jet or plasma CNC cutters, both have some pros and cons. However, before I dig into that, let me explain what a water-jet CNC machine and a plasma CNC machine is.

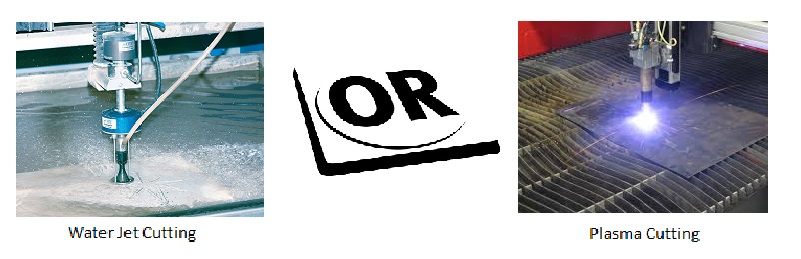

Water-jet cutting: This type of CNC cutter uses a thin stream of water, moving very fast, under extreme pressure to gnaw the material it is commanded to cut. The Pure Water Jet machine tools utilize only water and are mainly used for slicing softer materials like foam or rubber. On the other hand, the abrasive water-jet machines add a rough component to the water so that its flow can cut stronger materials like ceramics and metal.

Plasma cutting: A CNC plasma cutting machine generates electrically semi-conducting high temperature plasma jet to melt the metal it is needed to cut. The machine uses an electrical arc to generate the gas plasma and the jet becomes so hot that it can slice various metals.

In order to compare the differences between water-jet and plasma cutting machines, I will concentrate on the factors that a businessman needs to consider before opening his purse.

- Price of the machine: Price is a huge factor for any type of business investment and plasma cutting CNC machines wins in this regard. Most of the industrial plasma cutting machines are priced below $100,000. On the other hand, CNC water-jet machines feature a high pressure intensifier pump and thus, their price starts from $100,000 and the best quality machine can be as costly as $350,000.

- Operating cost: In terms of operating cost, plasma machines win once again. The hourly operating cost of a CNC Plasma Cutting is only $15. Water-jet is very expensive compared to plasma cutter. The average operating cost of a water-jet cutting machine per hour is not less than $30.

- Production rate: Operating cost can’t be calculated without considering the production rate of a machine. Production rate is calculated by comparing the cutting speed. While calculating the production rate, you must consider the number of cutting tools used by the machine. If a machine has 3-4 cutting tools, it will obviously cut more pieces of metal within 60 minutes. If you compare a CNC plasma cutter with a CNC water-jet, featuring just one cutting tool, plasma beats water-jet. A plasma cutter can cut 60 to 200 inches per minute whereas water-jet can cut a maximum 15 inches per minute.

- Cut-edge quality: Cut-edge quality is determined by the squareness of the finished edge and the level of dross. This is one department where water-jet beats plasma cutters hands down. Plasma cutting always causes edge bevel angle and dross.

- Precision of sliced parts: The actual part size, after sliced by the machine, is often different from the programmed part size. The closer an actual part size is to the programmed part size, the better is the cutting precision. You should also measure the kerf width while determining the precision of cuts. Water-jet offers better cut part precision than a plasma machine.

- Ability to cut different items: You must consider what type of materials you can cut using your machine before ordering it online. Water-jet CNC machines can cut any type of metal and non-metal material. On the other hand, plasma can cut only conductive metals. In fact, it can cut only stainless steel, mild steel and aluminum.

So, as you can see, neither plasma nor water-jet is the undisputed winner in this battle between CNC machines. You should invest in a machine that fulfills your main requirements. For example, if you want to cut different types of things and cut quality is crucial to you, you should buy a water-jet CNC machine. On the other hand, if you are going to use the machine to slice only conductive metals and want to keep operating cost as low as possible, it is wise to invest in a CNC plasma cutter.

The company Ajan Electronics specializes in no break power supply systems, cnc plasma cutting machine and lathes.The firm manufactures and exports machines with its own technology and these facts brought the firm to a powerful position in the world.