Nowadays, most companies have started using mainly plastic in their manufacturing process and are trying to eliminate the use of other traditional materials that were previously used. Today, most of our home appliances such as the coffee maker, the laptop, the stereo etc., are manufactured with different types of inexpensive but very durable plastics. Although the market is flooded with various plastics that can be found extremely cheap, the manufacturers need to make sure that their plastic is in compliance with the EU Product Safety requirements. That is why different factors are considered regarding the usage of these plastics.

The safety standards consider 3 main categories of plastic components and they are as follows:

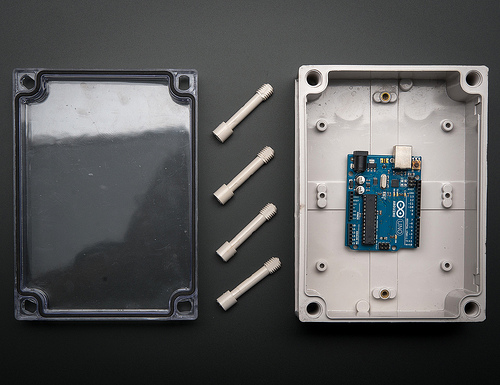

– Plastic enclosures that need to meet the mechanical, electrical and flammability requirements.

Internal components that represent specific materials made out of plastic that are located inside the enclosure like ducting, card guides, wiring boards, tubing and connectors. The plastics that would be used for these components are required to meet the requirements for flammability but only for inside the enclosure. Here there may be more electrical and mechanical requirements which will depend on the usage.

– Decorative parts are usually required to cover minimum flammability safety as they are located on the outside of the fire housing.

The fire enclosures are certainly made with the flammability requirements in mind. They are designed to act as a barrier for any flames that may have appeared on the inside of the enclosure thus preventing fire from spreading and the appearing of dangerous situations. The electrical ones are limiting the access to high energy levels and hazardous voltages and TNV. Mechanical enclosures prevent physical or mechanical hazards that may cause injuries.

– The custom plastic enclosures are designed to fulfil other EU regulation like REACH compliance and RoHS.

The REACH compliance is restricting the use of some dangerous chemical substances in the plastics that are used for the manufacturing of the product housings. It strictly follows that there is no danger to human health and that the plastics produced could be recycled thus not causing harm to nature. The RoHS directive makes sure that there are no hazardous substances in the production of electronic equipment. It strictly forbids the use of six dangerous substances that have been used in the past for the production of electronics. The manufacturers have to pass the EU regulations and will receive a certificate that can put their customers to rest as they will know that their chosen supplier follows all the safety rules.

Saving nature has been a number one priority of people since we have realized how much harm we cause with every action we take. That is why the European Union is trying to enforce these laws so that we can make sure that we are eco friendly. Yes, the more restrictions there are on the materials and the chemicals that can be used for the production of custom plastic enclosures, the more expensive they will be, but at the end of the day we cannot put price on health and safety.

An article by Paul Winchester. The information was offered by the team of simcobox.com