[youtube http://www.youtube.com/watch?v=PVRgIXLWDHs]

According to an analysis by PWC, the majority of companies within the Engineering industry face a common set of modern day challenges. Although there are a number of challenges listed, looking beyond the surface it becomes obvious that the underlying theme is one of a lack of business integration, transparency and insight.

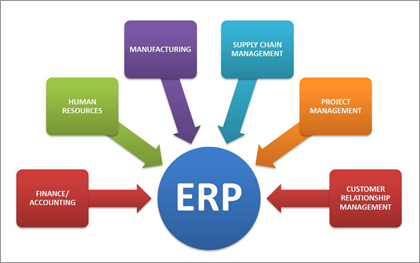

On the surface these challenges revolve around the management of risk and effective project management, proper management of relationships and responding to sustainability movements. Proper and effective use of Enterprise Resource Planning software within the Engineering industry could therefore be the answer.

Proper communication and integration of all business activities using ERP can produce greater business insight, greater insight leads to better and more informed decision making, and ultimately less risk and an improved product. The Lotus Formula 1 Team are a great example of how using ERP software in the Engineering industry, such as Dynamics, can work effectively. The team can use Microsoft Dynamics to collect live, accurate information, make more informed decisions, improve manufacturing productivity, avoid wasted resources, and deliver information safely and quickly to remote employees with the aim to build a faster car with which to win more races - highlighting that it really is about perfecting the processes that take place in building the final product.

Often, unexpected risks can lead to disruptions and therefore disputes between the parties involved. These disputes are time consuming and costly for a business to peruse, and ultimately detracts from the main objective: to complete the project on time. The ideal solution is to better manage the risk from the very beginning through such greater transparency and insight. Dynamics gives the ability for accurate ‘capable to promise', meaning that based on these insights managers are able to give more accurate project completion dates, and sticking to the planning route all the way through the project means they are much more likely to meet these deadlines, and being able to keep track of what process is happening and where it is happening within the business will ultimately improve customer satisfaction and reduce the risk of disputes ever even occurring.

The implementation of an Enterprise Resource Planning solution is still seen by many as a lengthy and drawn out process that takes valuable time away from their core activities. Yet in reality, this short term view can be counterproductive and have negative long term consequences as these familiar challenges come to light time and time again. Before anything else, the way in which the business ‘thinks' first needs to be modernised; the underlying foundations of a house need to be firmly established before the main bricklaying actually takes place; as it is with the processes and standard practices of a business.

The implementation of ERP software results in the re-engineering of business process, highlighting and eliminating tasks that do not add value while promoting tasks which do. It involves viewing your business from an alternative perspective and consequently re-thinking the way in which it works. Once these redundant tasks are recognised, they are removed, thus streamlining business processes and maximising efficiency throughout. The benefits of implementing ERP systems into the Engineering industry are crucial, and are part of the winning formula for a modern and flexible organisation to make the most of the economic upturn.

Craig Such is the Director of Azzure IT-a Sheffield based provider of end-to-end IT solutions.